Shd High Pressure Horizontal Mining Multistage Boiler

Basic Info.

| Model NO. | SHD85-45/10 |

| Working Pressure | High Pressure Pump |

| Influent Type of Impeller | Single Suction Pump |

| Position of Pump Shaft | Horizontal Pump |

| Pump Casing Combined | Verticaljoint Surface Pump |

| Mounting Height | Suction Centrifugal |

| Impeller | Closed |

| Usage | Pump, Pumps, Condensate Pump, Circulating Pump |

| Seal Type | Mechanical Sea or Packing Gland Seal |

| Material | Cast Iron, Cast Steel, Stainless Steel, Bronze |

| Transport Package | Plywood Case |

| Specification | 2200*900*1500mm |

| Trademark | SEMHAI or OEM |

| Origin | China |

| HS Code | 8413709990 |

| Production Capacity | 1000000sets/Year |

Product Description

Product Description

SHD, SHDG single-suction multistage segmental type centrifugal pump for conveying water or physical and chemical properties similar to water without solid particles. SHD pumps transmission fluid with temperature below 80 ºC, suitable for mines, factories and urban drainage. SHDG pumps transmission fluid with temperature below 105 ºC, which is suitable for boiler feed pump or delivery of hot water and other similar occasions.

Structural features

SHD, SHDG type pumps made from stator, rotor, bearings and shaft seal.

1, Stator part: mainly by inhalation, middle, spit section, guide vanes, etc., clamping segments with tension bolts to be running part. SHD-type pump with horizontal inlet and vertical outlet, SHDG type pump with both vertical inlet and outlet.

2, Rotor parts: the main by the shaft, impeller, balance plate and bushings and other components. The shaft transfer power to the impeller to make it work; axial force is balanced by balance plate; both ends of the shaft equipped with replaceable shaft sleeve for protection.

3,Bearing part: 2 type of bearings: rolling bearings and sliding bearings:

Sliding bearing mainly by bearing body, bearing caps, bearing, dust disk, oil level gauge, rejection mooring rings and other components, lubrication of thick oil; Rolling bearing main body, bearings and gland, using grease lubrication.

4, Shaft seal parts: mechanical seal or packing seal, mainly by water segment and sealed body filler, retaining ring components at tail cover letter. Seal chamber liquid with function of the water seal, water-cooled and water lubrication. SHD pump seal water from pressure water inside pump. SHDG seal water from cooling water, normal temperature water outside pump.The pressure of seal water should be higher than seal chamber 0.05-0.1MPa, the pressure of cooling water to be 0.15-0.3MPa.

In addition, the pump is directly driven by a prime motor through flexible coupling. The pump is clockwise rotation, seem from the prime motor end.

SHD, SHDG single-suction multistage segmental type centrifugal booster pump can be driven by electric motor or diesel engine.

Detailed Photos

In multistage centrifugal pumps, because of the high thrust that is generated due to the impellers facing in the same direction, there will be a thrust balance device i.e balance disc or balance drum which reduces the thrust to a level which can be managed by a standard sized thrust bearing.Impeller material can be cast iron, cast steel, stainless steel and bronze.Flexible couplings

Unlike rigid couplings, flexible couplings can accommodate some movement e.g. vibrations and thermal expansion without damage. This makes them ideal for applications where there is a degree of unavoidable misalignment between the drive and pump shafts. As they can absorb vibrations well, they can also be used to reduce excessive operating noise. With these benefits come a more complex, expensive design. However, as flexible couplings protect the shaft and bearings from damage and premature wear, there are maintenance savings to be had in the long run.

We use wear-resisting disc coupling or pin coupling. Packing seals have been the most widely used sealing solution for many years. Packing seals use rope-like materials that wrap around the shaft of a pump, filling in dead space and minimizing fluid loss. Over time, however, fluid loss will increase as the gland packing material begins to wear down and may impair regular lubrication or reduce ease-of-replacement that is required to function properly.

Mechanical seals are preferred over traditional packing seals in diverse applications during which leakage problems should be avoided. Mechanical seals are more durable than their predecessors and are designed to take much more punishment. Basic mechanical seals use multiple sealing points to nearly eliminate any leakage issues.

Product Parameters

| Flow rate | 6-1000m3/hr |

| Head rate | 25-650m |

| Speed | 1450-2900rpm |

| Medium temperature | 0-105 ºC |

| Diameter | 40-350mm |

Product Application

Pressure boosting systems commonly employ these pumps. These circumstances usually demand a constant flow and pressure. Some of the most common projects that will use a horizontal multistage pump are:Mine dewatering

High density living

Snow making

Boiler feed systems

Reverse Osmosis

Industrial applications

Condensate

High pressure cleaning/wash down facilities

Jacking pumps for fire hydrant systems

Irrigation and fire hose feel supply

Showers

Co generation

Spray

Pressure Boosting

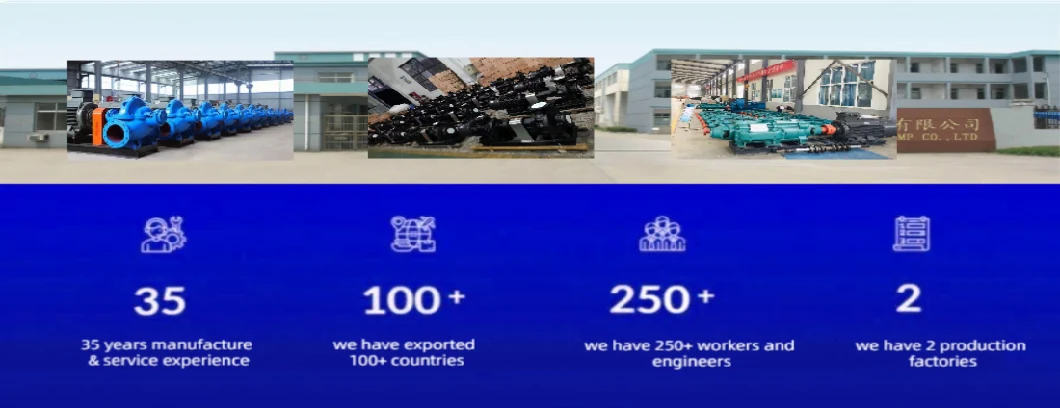

Facilities & Equipments

FAQ

A. What are the multi stage pump parts?

The multistage pump parts are very similar to those of the standard Centrifugal pump except for the Multistage Centrifugal pump where the additional parts are diffusers which efficiently channel the fluid into the eye of the impeller or to the following stage. In the side channel pump, there are intermediate plates with the scalloped side channel and liquid parts.

In multistage centrifugal pumps, because of the high thrust that is generated due to the impellers facing in the same direction, there will be a thrust balance device i.e balance disc or balance drum which reduces the thrust to a level which can be managed by a standard sized thrust bearing.

B. How does a multi stage pump work?

A multistage pump operates by one impeller feeding into the next impeller and the number of impellers required depend on the discharge pressure requirement. Liquid enters the pump and then passes through the various number of impellers in a sequence from the left to right.

C. What are the applications and uses for multi stage pumps?

The applications for multi stage pumps are many and varied and can be used for delivering water to high rise buildings, reverse osmosis (RO), boiler feed water, spraying, high pressure cleaning, water works, heating, condensate, fuel delivery, oil and gas production, power generation & mining and other high pressure and temperature applications..

D. What are the different types of multi stage pumps?

Types of multistage pumps include;

Horizontal Multistage Centrifugal pump (above ground)

Vertical Multistage Centrifugal pump (above ground)

Submersible/Sump pump types

Side Channel pump

Combination pumps i.e Centrifugal low NPSH first stage with side channel additional stage.

Horizontal split case pump

Vertical Turbine pump

Sanitary Multistage pump

E. What are the advantages of using a multi stage pump?

If we were to compare the Centrifugal multi stage pump to a high pressure duty pump - the Centrifugal multi stage pump even though it is more complex and costly, it would probably be a better hydraulic fit, have a better efficiency and be more reliable. With its hydraulic modules, the ability to supply additional impellers and its ability to trim those impellers, the duty point can me met exactly without compromise. The selection is more likely to be close to 'BEP' and will run efficiently and reliably.

Multi stage pumps can be configured to have an interstage bleed off if there are multiple duty points required. It may be possible to run a multistage pump at a lower speed than a single stage centrifugal pump which may offer an efficiency advantage but it will certainly run much quieter which is an important consideration in today's world. A 3 dBA increase represents a doubling of sound as the sound scale is logarithmic.

F. What is difference between a single stage and a multi stage pump?

A single stage pump uses one impeller whereas a multi stage pump uses 2 or more impellers (some manufacturers use 80 or more impellers).

There are additional components in a multi stage pump which are required for channelling the fluid from the first stage to the following stage i.e diffusers.

Multi stage pumps have a thrust balance device and there may also be intermediate bearings (lubricated by the pumpage) to steady the shaft plus other minor differences.

G. How do you read a multistage pump curve?

You read a multi stage pump curve in exactly the same way as you read any other pump type curve however some manufacturers will publish single stage curves which means that this has to be multiplied out to establish the number of stages required, however be aware that the side channel pumps have their maximum power at zero flow and the power decreases with increasing flow which is the reverse of a centrifugal pump.

H. What is the difference between a vertical multistage pump and a horizontal multistage pump?

The main differences between a vertical multi stage pump and a horizontal multi stage pump are;

1.The orientation of the pump

2.The vertical multi stage pump is above ground and may be used where there are space limitations however the motor needs to be removed before maintenance can be performed.

3.Vertical multi stage pumps are used in some applications where the motor needs to be lifted from the sump so that the unit can be maintained. It is common in vertical pumps for the thrust load to be taken by the motor e.g. VTP turbine pumps which have electric motors specifically designed for this type of pump to eliminate the need for a thrust bearing in the pump resulting in less complexity and costs. VTP pumps can be produced with column lengths of more than 100 metres.

4.Horizontal multi stage pumps are mounted using feet which for high temperature applications are a special design to allow for thermal growth and thus avoid operating issues due to expansion and contraction. They would need to be aligned with the electric motor. On vertical pumps, the mounting is perhaps simpler i.e for sump pumps, a support plate would be fixed with standard bolting and generally no alignment is required as the motor is flanged and it is self aligning with the corresponding register.

I. Which type of multistage pump is more commonly used in industry?

The most common type of multi stage pump used in Industry is the horizontal multi stage pump and vertical multi stage pump (above ground) mounted centrifugal pumps. However, multi stage side channel pumps would also be relatively common along with the vertical turbine pumps.

SEMHAI can offer a full range of Flowserve's Multi stage pumps.We provide localised technical support & on-site service engineering to support your operational needs.